Manage FF&E specification, procurement, and product data at scale. Take on bigger projects with confidence and grow your firm with Fohlio. Schedule a demo or book a consultation with one of our account managers to explore these features today.

“If you cannot measure it, you cannot improve it” – Lord Kelvin.

Beyond the process of purchasing FF&E and construction materials, procurement is, in its own right, both a science and an art. Good procurement practices lead to the streamlining of operations, the reduction of raw material prices and costs, and the selection of better product sources.

Ultimately, it results in the increase of profits for the firm.

For smaller procurement firms, and especially in the beginning, using personal judgment and following your gut may suffice. Lower prices and faster turnaround times are good achievements to begin with, as well.

But if you find that your procurement operations have grown bigger, or if you’re thinking of growing your procurement firm, then it’s time to standardize your workflows. At Fohlio, we’re big believers in standardization: It’s the most reliable way of scaling a business.

Consider implementing these key performance indicators to measure your procurement workflows’ success, and control purchasing expenses, quality, cost, and time.

Quality:

- Compliance Rate

- This answers the question of whether your suppliers meet the business requirements.

- This can be defined in the contract by clearly defining boundaries between the supplier and the company.

- Through defining the terms like delivery time, limitation on the number of defects, and reaction time in case of delays, you can control maverick spending.

- Number of Suppliers

- Understand how dependent you are on each of your suppliers.

- Having alternate vendor options available manages your level of risk of dependency.

- Supplier Quality Rating

- Speed and volume become outliers when you do not factor in quality with your suppliers.

- This varies according to the needs set by the company. In an ideal scenario, suppliers would look like this: one that provides high-quality goods or services with fair costing, average to early lead time with quick reaction time, and warranty.

- Supplier Defect Rate: Evaluate your suppliers’ individual quality.

-

- This measures whether the materials of the supplier are substandard or of good quality.

- Sub-standard materials or services can cost you more in the long run. Shorter life cycles and unreliable materials have been proven to be a cause for overspending on a project.

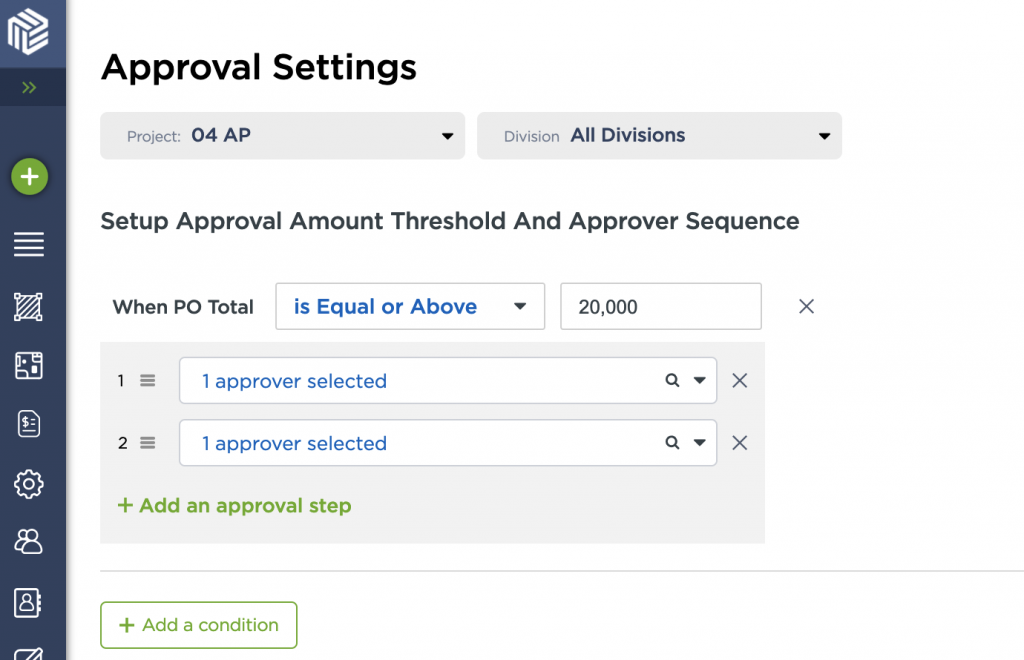

Learn more: How to Track Changes, Set Approval Thresholds for Purchase Orders, and More

Delivery:

- Purchase Order Cycle Time: Know who to address your urgent orders to.

- This covers the entire purchasing cycle and includes internal processes: Order creation, approval, delivery, invoice generation, and payment are counted as a whole in this KPI.

- Categorize your suppliers according to how they fit in with delivery time.

- In case of emergencies where you would need to fulfill an order quickly, your best chances would lie on which supplier could provide the material with the best value on the shortest notice.

- Supplier Availability: Measure suppliers’ capacity to respond to demand.

- This analyzes a supplier’s capability to respond to a demand whether it be by speed or volume.

- To measure this: number of times items were available with vendor/frequency of orders placed.

- An ideal percentage for the availability of suppliers would play at around 90%.

- Lead Time

- This is the time required to fulfil an order.

- Commonly mistaken for P.O. cycle time, lead time is actually the duration of delivery from the customer’s point of view.

- This matters greatly because this is the basis for your performance according to your customers.

Price

- Cost of Purchase Order: Control the internal costs incurred by each purchase.

- This KPI takes into consideration all the costs associated with acquiring the goods needed for completion. This may include indirect and direct costs such as freight, transaction costs, etc., which add to the full price of acquiring a certain good or service.

- Procurement Cost Reduction:

- Simply measures the percentage of costs saved during negotiation.

- Price competitiveness

- This is the price difference between the posted market price and the supplier’s offer.

- This could also be the difference between the extent of the services being offered by the vendors.

There are a multitude of ways to monitor and ensure the improvement of your procurement process. Implementing company-wide KPIs is just one method.

Additionally, you can add many more KPIs to measure different workflows, efforts, and initiatives.

Monitoring these numbers will allow you to have a better understanding of your company’s status and performance, allowing you to make significant improvements to your execution in order to meet your strategic objectives. Knowing and measuring the essential KPIs will aid you in achieving faster results.

https://www.cflowapps.com/procurement/procurement-kpis/

https://www.datapine.com/kpi-examples-and-templates/procurement

https://www.netsuite.com/portal/resource/articles/accounting/procurement.shtml

Manage FF&E specification, procurement, and product data at scale. Take on bigger projects with confidence and grow your firm with Fohlio. Schedule a demo or book a consultation with one of our account managers to explore these features today.

Expore Fohlio

Learn how to:

- Save days of work with faster specification

- Create firm-wide design standards

- Automate and centralize procurement

- Keep your whole team on the same Page

- Manage product data

- Track budget against cost in real time.

- Prepare for asset valuation

Published Jan 10, 2022