Delays, overruns, and quality issues—what if the answer to these common project pitfalls lies in your procurement process?

It’s about more than just buying materials; it’s about ensuring quality, controlling costs, and keeping projects on schedule. Good procurement practices build strong supplier relationships, integrate sustainability, and manage risks effectively.

Here’s how strategic procurement can improve design-build outcomes, helping you achieve better quality, cost savings, and timely project completion.

Case Study: How A Design and Procurement Firm Built Specifications 4x Faster and Saved Hours Of Work With Fohlio

Scope of Procurement in Design-Build

At its core, design-build procurement projects involves sourcing and acquiring the necessary materials, services, and subcontractors to execute the project.

This process goes beyond simple purchasing; it includes negotiating contracts, managing supplier relationships, and ensuring that all procured items meet the required standards and specifications. By understanding and optimizing the role of procurement, design-build teams can significantly enhance their project's success.

Image Reference

Key Stakeholders

Procurement Managers:

- Responsible for sourcing materials (FF&E purchasing), services, and subcontractors needed for the project.

- Negotiate contracts and terms with suppliers to ensure cost-effective procurement.

- Manage procurement timelines to align with project schedules and milestones.

Project Managers:

- Oversee the entire design-build project from inception to completion.

- Coordinate between different stakeholders, including designers, contractors, and clients.

- Monitor project progress, budget, and schedule to ensure timely delivery and quality.

Designers:

- Develop the creative and technical aspects of the project through FF&E/OS&E specification writing, including architectural and engineering designs.

- Collaborate closely with procurement and project managers to specify materials and standards.

- Ensure that design intent is maintained throughout the procurement and construction phases.

Suppliers:

- Provide FF&E, OS&E, and services required for the project.

- Work with procurement managers to fulfill orders, deliver goods, and meet project specifications.

- Maintain quality standards and adhere to contractual obligations during the procurement process.

Read more: Considering Value-Add Services? Here's How a Design Firm Built an In-House Procurement Department With Fohlio (and Increased Profits!)

Influence on Quality

In design-build projects, procurement significantly shapes the quality of outcomes by:

-

Compliance: Ensuring that procurement processes adhere to FF&E (Furniture, Fixtures, and Equipment) and OS&E (Operating Supplies and Equipment) standards, meeting brand specifications and lifecycle expectations.

.png?width=881&height=504&name=t-1%20(3).png)

-

Design Integration: While meeting standards, there's often a challenge in aligning FF&E and OS&E procurement with the intended aesthetic and functional goals of the design. This balance is crucial to achieving the desired final design quality, enhancing both the project's aesthetic appeal and functional integrity.

.png?width=1602&height=1120&name=product%20info%20(8).png)

FF&E and OS&E Cost Management

Effective procurement practices play a crucial role in managing costs related to Furniture, Fixtures, and Equipment (FF&E) and Operating Supplies and Equipment (OS&E) by:

-

Strategic Budget Allocation: Strategically allocating budgets to procure necessary materials, services, and subcontractors within approved project budgets. This involves categorizing FF&E and OS&E items and identifying categories that impact the overall budget.

.png?width=708&height=540&name=t-6%20(4).png)

-

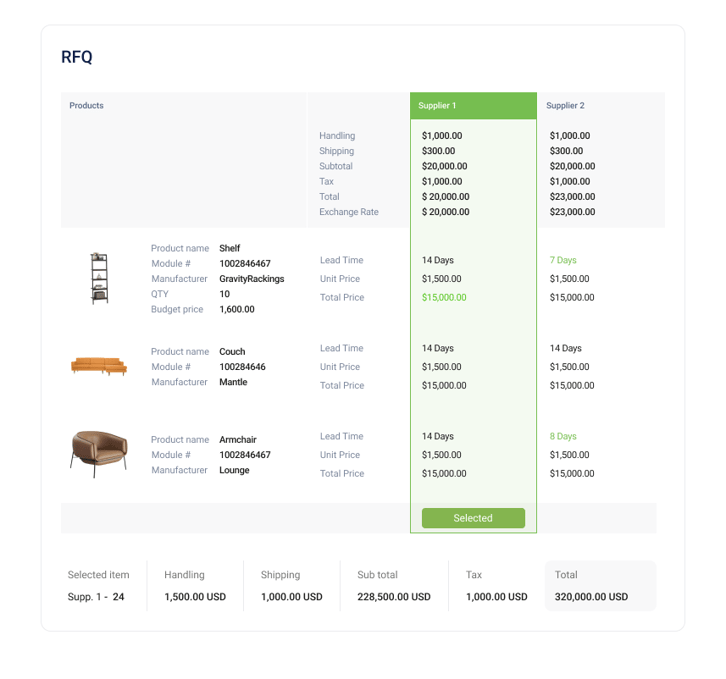

Cost-Control Measures: To manage expenses by implementing rigorous cost-control measures through competitive bidding, negotiation, and value engineering. Utilizing metrics such as planned versus actual spending, and comparing quotes and historical pricing data can inform negotiations and help drive down costs effectively.

.png?width=1034&height=454&name=t-6%20(5).png)

-

Balancing Cost, Quality, and Design: Ensuring a delicate balance between cost considerations, quality standards, and design aspirations to achieve the desired project outcomes without compromising on quality. This approach helps maintain project standards while managing costs efficiently throughout the procurement process.

Lead Time and Tracking Efficiency

Procurement plays a critical role in ensuring project timeliness and efficiency by:

-

Facilitating Timely Delivery: Procurement teams work diligently to source materials that meet the project schedule and milestones. This involves meticulous planning, early engagement with suppliers, and establishing clear delivery timelines.

.png?width=881&height=504&name=library%20(5).png)

-

Proactive Supply Chain Management: Proactive supply chain management is key to minimizing delays. This involves closely monitoring the supply chain to identify and address potential disruptions before they impact the project. Effective logistics planning ensures that materials are transported efficiently and safely to the project site. This includes selecting reliable transportation methods, optimizing routes, and ensuring that all logistical details are handled smoothly.

.png?width=646&height=428&name=role%20selection%20(6).png)

-

Mitigating Risks and Enhancing Efficiency: Procurement teams implement risk mitigation strategies to manage potential delays and material shortages, developing contingency plans to address these challenges. Efficiency is enhanced through advanced procurement software that provides real-time updates on orders, deliveries, and inventory levels, allowing for quick decision-making and adjustments. Continuous monitoring and flexibility enable procurement teams to adapt to changes and unforeseen circumstances, ensuring smooth and efficient project progression.

.png?width=945&height=544&name=product%20info%20(6).png)

In summary, effective procurement is vital to the success of design-build projects, directly influencing quality, cost management, and project efficiency.

By ensuring compliance with standards, integrating design and procurement efforts, strategically managing budgets, and maintaining efficient lead times and tracking, procurement teams help deliver high-quality outcomes on time and within budget. Strong supplier relationships and proactive risk management further enhance project stability and success.

Founded in 1978 with a vision for world-class design in healthcare, senior living, and multifamily projects, this company faced inefficiencies in their manual specification and procurement practices. Managing design specifications in Excel and relying on third-party procurement hindered smooth operations, leading to data silos and rework.

Enter Fohlio. The company's adoption of Fohlio revolutionized their processes, reducing a cumbersome four-step reporting procedure down to one streamlined process. The web clipper and automated reports saved significant time, transforming how they prepared proposals and presentation documents.

Moreover, Fohlio empowered them to bring procurement in-house, despite initial inexperience. With tailored support from Fohlio's team, they built a robust procurement process, reclaiming profits and accelerating project timelines.

Today, this company continues to thrive, delivering high-quality facilities nationwide, fueled by streamlined operations and empowered design and procurement capabilities.

As the industry evolves, the importance of procurement in achieving successful design-build outcomes will only grow.

Future trends in procurement for design-build projects include the increased use of advanced technologies for real-time tracking and analytics, a greater emphasis on sustainable and eco-friendly materials, and the continuous development of more robust risk mitigation strategies.

By staying ahead of these trends and continuing to optimize procurement processes, design-build teams can ensure they deliver exceptional projects that meet both current and future demands.